01

Veterinary PAWSOME Orthopedic 1.5/2.0/2.4/2.7/3.5mm plate Instruments Set

specification

| Title | Veterinary Orthopedic Instruments Set 1.5/2.0/2.4/2.7/3.5mm system |

| Properties | Veterinary orthopedic surgery |

| Feature | Sustainable |

| Type | Handheld, Pet Product |

| Application | Veterinary Surgical |

| Place of Origin | Changzhou,Jiangsu, China |

| Brand Name | Pawsome |

| Target Species | small bones like hand feet small animals |

| Warranty | 1 Year |

| MOQ | 1 SET |

| Logo | Customized Logo Availabled |

| Series | Veterinary trauma system |

| Packaging and delivery | |

| Selling units | Single item |

| Single package size | 45X35X32 cm |

| Single gross weight | 6KG |

What is the Veterinary Orthopedic Instruments Set 1.5/2.0/2.4/2.7/3.5mm used for?

-

Acetabular Plate

Acetabular Plate -

2.7mm X Type Plate Cuttable

2.7mm X Type Plate Cuttable -

L Type Curved Plate

L Type Curved Plate

-

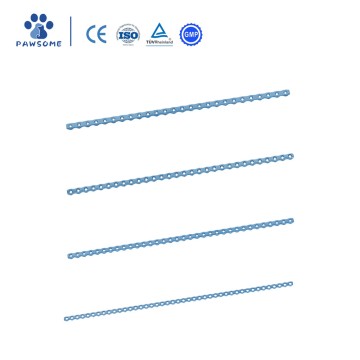

Veterinary 2.4 Straight Plate Cuttable)

Veterinary 2.4 Straight Plate Cuttable) -

Veterinary 2.7 Distal Femoral Plate

Veterinary 2.7 Distal Femoral Plate -

Veterinary Stainless Steel Straight Reconstruction Plate

Veterinary Stainless Steel Straight Reconstruction Plate

specification

| Details | Specification | Qty. |

| Reduction Forceps with point-Medium | 160mm | 1 |

| Reduction Forceps with point-Small | 135mm | 1 |

| Self-centering Bone holding Forcep | X-Small | 1 |

| Reduction Forcep | 170mm | 1 |

| Self-centering bone holding Forcep | 190mm | 1 |

| Wire Cutter | 2.5mm | 1 |

| End Cutting Forcep | 2.5mm | 1 |

| Wire Guider | Ø20mm | 1 |

| K wire punch | 1.5-2.5mm | 1 |

| K Wire Bender | 1 | |

| Ruskin Ronger | 2mm | 1 |

| Bone Rasp | 1 | |

| Double End Periosteal Elevator | 5mm | 1 |

| Mini Hohman Retractor | 6mm | 1 |

| 8mm | 1 | |

| 15mm | 1 | |

| Screw Holder | Small | 1 |

| AO Plates Bender | 1.5/2.0/2.4mm | 1 |

| 2.7/3.5mm | 1 | |

| Depth Gauge | 0-30mm | 1 |

| 0-60mm | 1 | |

| Screw Driver | SW1.5 | 1 |

| SW2.5 | 1 | |

| AO Quick Coupling T Type Handle | 1 | |

| AO Quick Coupling Countersink | Ø4mm | 1 |

| Ø6mm | 1 | |

| AO Quick Coupling Screw Tap | 1.5mm | 1 |

| 2.0mm | 1 | |

| 2.4mm | 1 | |

| 2.7mm | 1 | |

| 3.5mm | 1 | |

| Double Drill Guider | 1.1/1.5mm | 1 |

| 1.5/2.0mm | 1 | |

| 1.8/2.4mm | 1 | |

| 2.0/2.7mm | 1 | |

| 2.5/3.5mm | 1 | |

| LC-DCP Drill Sleeve | 1.5 mm | 1 |

| 1.8mm | 1 | |

| 2.0mm | 1 | |

| 2.5mm | 1 | |

| Bone Plate Model | 4 | |

| Skin Retractor | 2 | |

| Self Retaining Retractor | 140mm | 1 |

| Drill Bit | 1.1mm | 1 |

| 1.5mm | 1 | |

| 1.8mm | 1 | |

| 2.0mm | 1 | |

| 2.5mm | 1 | |

| 2.7mm | 1 |

product description

What is the function and advantage of 1.5/2.0/2.4/2.7/3.5mm veterinary plate instrument set?

Veterinary Orthopedic Instruments Set 1.5/2.0/2.4/2.7/3.5mm, this is the "weapon spectrum" on our orthopedic operating table. They are not used for a specific operation, but a standardized, modular internal fixation tool system to adapt to bone screws, steel plates and other supporting implants of corresponding diameters.

So the size of the instrument package you choose depends on the diameter of the screw you want to screw, and the size of the screw depends on how thick the bone you want to fix is and how much force it bears!

This instrument package not only has a full set of instruments needed for surgery, but also has a place to place plates and screws.

The function of this instrument package is:

1. Bone screw:

This is the most basic and most important function! Screw various types of bone screws (cortical bone screws, cancellous bone screws, lag screws, locking screw heads) into the bone.

2. Place and fix the steel plate:

Apply stainless steel plates of various shapes and lengths (straight plates, T-shaped plates, L-shaped plates, reconstruction plates, tubular plates, etc.) to the bone surface and fix them firmly with screws.

3. Perform fracture reduction and temporary fixation:

Use the reduction forceps, bone holding forceps, etc. in the instrument to put the broken bones back to the correct position and temporarily stabilize them.

4. Drilling, depth measurement, tapping (if necessary):

Prepare the bone channel for screwing in the screws.

5. Handle steel wires/Kirschner wires (some packages include or are compatible):

Used for fixation techniques such as cerclage and tension band.

Our production process

1. Raw Material

There are two kinds of materials: stainless steel and titanium. we have sufficient raw material for production.

2. Mechnical Test

All of our material will have strictly mechnical test,To ensure the stable performance of the products produced and meet the standards of CE and ISO

3. Production

After the materials are tested and qualified, we will enter the production stage according to industry standards. We use imported advanced CNC machines for precise cutting, molding and production. We have nearly 40 imported CNC machines, which greatly ensures the efficiency of our production speed.

4. Quality checking

After production is completed, we will test the physical and chemical properties of the finished product, such as pressure resistance, corrosion resistance, etc., as well as 100% inspection of the product's appearance, size, and surface to ensure the product is perfect.

5. Packing

After the quality inspection, we will pack the products according to different orders of customers. We have sterile packaging and non-sterile packaging. After the products are packed, we will use bubble film to protect them, and then put them into cartons to ensure that the products are not damaged during transportation.

6. Delivery

We will place the packaged parcels according to different transportation channels, and then wait for express companies such as DHL/FEDEX/UPS/TNT to pick up the parcels and deliver them to each customer. We have rich transportation experience to ensure that customers receive their goods safely and efficiently through the most cost-effective channels.