Leading ODM Manufacturers for High-Quality Saw Blade Solutions and Innovations

When seeking top-notch Saw Blades, it's essential to find dependable custom solutions tailored to your specific requirements. At Paswome, we pride ourselves on offering high-quality saw blades designed for various applications, ideal for factories and suppliers. Our products are crafted with precision to ensure durability and efficiency in every cut. Understanding your sourcing challenges, we provide a diverse selection, from carbide-tipped blades to high-speed steel options. Our unwavering commitment to quality ensures you receive a reliable partner in your production needs. With competitive pricing and dedicated support, we equip your business with the best saw blades available. Choosing Paswome signifies a commitment to reliability, innovation, and high performance, enhancing your operational efficiency. Let’s collaborate to meet your cutting needs effectively!

Practical Strategies for Saw Blades Trusted by Pros Manufacturers You Can Rely On

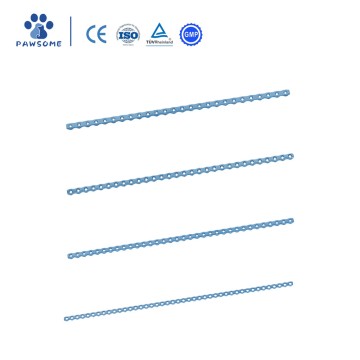

When it comes to cutting and shaping materials in various industries, reliability and precision are paramount. Professionals trust tools that deliver excellent performance consistently, and saw blades are no exception. Selecting the right saw blades can make a significant difference in the efficiency of production processes, ensuring that projects meet deadlines and quality standards. This guide explores practical strategies for choosing saw blades that professionals in manufacturing have come to rely on. First, consider the specific materials you will be cutting. Different saw blades are designed for various materials, including wood, metal, and composite materials. Understanding the composition and density of the material allows you to select a blade with the appropriate tooth configuration, size, and coating. For instance, carbide-tipped saw blades provide durability and maintain sharpness longer, making them ideal for high-volume cutting tasks. Additionally, clients should prioritize blades that offer ease of maintenance and longevity, reducing replacement costs and downtime. Secondly, always assess your supplier’s reputation and experience in the industry. A trusted supplier will have a track record of providing high-quality blades consistently backed by reliable customer support. Exploring customer reviews, case studies, and industry certifications ensures you choose a vendor that aligns with professional standards. Investing in superior saw blades from reputable manufacturers not only enhances productivity but also contributes to overall operational safety in the manufacturing environment.

Practical Strategies for Saw Blades Trusted by Pros Manufacturers You Can Rely On

| Dimension | Material | Application | Blade Type | Recommended Use |

|---|---|---|---|---|

| 10-inch | Carbide-tipped | Crosscutting | Circular | Softwood, Hardwood |

| 7.25-inch | High Carbon Steel | Ripping | Circular | Plywood, OSB |

| 12-inch | Tungsten Carbide | Miter Cutting | Circular | Composite, Trim |

| 6-inch | Aluminum | Cutting Metal | Circular | Aluminum Sheets |

| 8-inch | Diamond | Masonry | Circular | Tiles, Concrete |

Best Way To Saw Blades Manufacturers You Can Rely On Service Backed by Expertise

E

Emily Carter

I was thoroughly impressed by the professionalism of the support team. They resolved my issues swiftly and with great expertise!

28 May 2025

S

Samuel Brown

Impressive quality! The customer support was quick and demonstrated a high degree of professionalism.

28 May 2025

L

Layla Cruz

I am amazed by the product quality! The customer service has been nothing short of excellent.

08 June 2025

M

Mila Peterson

High-quality and great service! The support staff is friendly and trained well.

11 June 2025

G

Gavin White

Fantastic quality! Every interaction with the support team was pleasant and efficient.

22 May 2025

M

Mia Clark

So happy with my decision! The product quality is impressive, and the service support was great.

14 May 2025